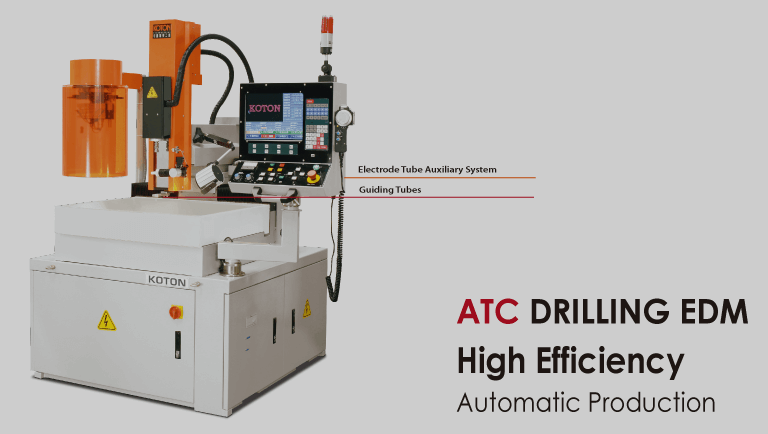

Feature

- C type structure.

- Mirror image function.

- Coordinates can rotate at any angle.

- Automatic copper tube deviation correction.

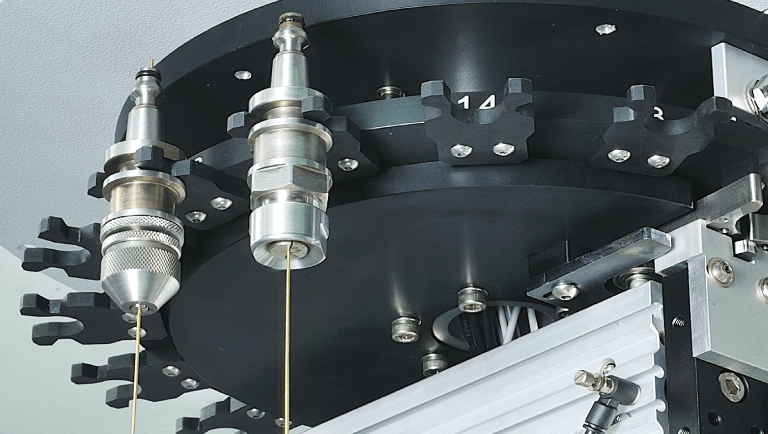

- Automatic 16 & 30 copper tube changers available.

- Direct and easy learning dialogue operation interface.

- Data could be input by USB, or transfer through network.

- Automatic edge, internal diameter finding, and centering.

- The machining coordinate can be input directly when NC program is not available.

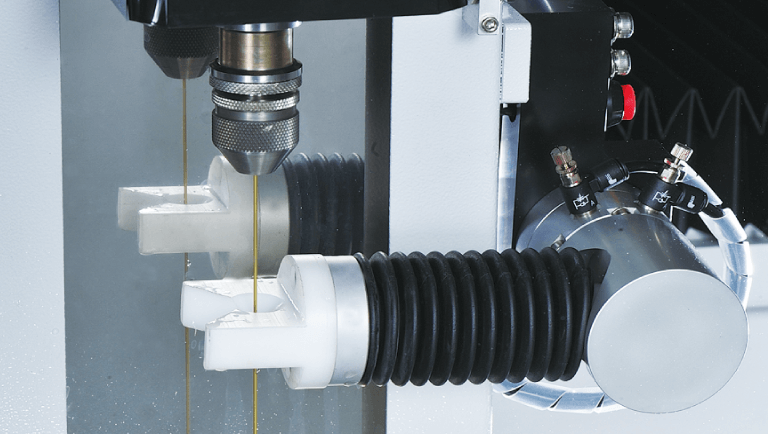

- Drilling capacity from 0.2 mm to 3.0 mm diameter brass or copper electrode tubes.

- Automatic illustrates the path of current and next drilling position with color.

- Precision servo motors on X,Y,Z axes provide excellent stability during drilling.

- The flushing medium used by this machine is distilled water - environment friendly.

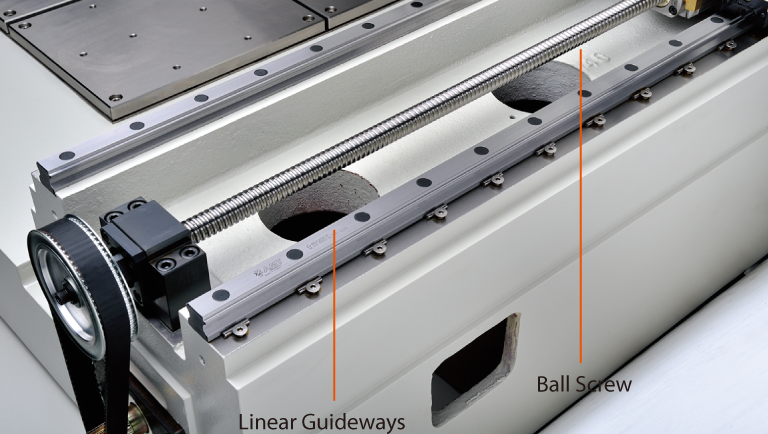

- Provide 1μ optical scale, linear slideway and ballscrew ensure very accurate movements.

- NC program G-code and DXF files could be directly read; Automatically finds the start cutting point and begins a fine hole drilling process.

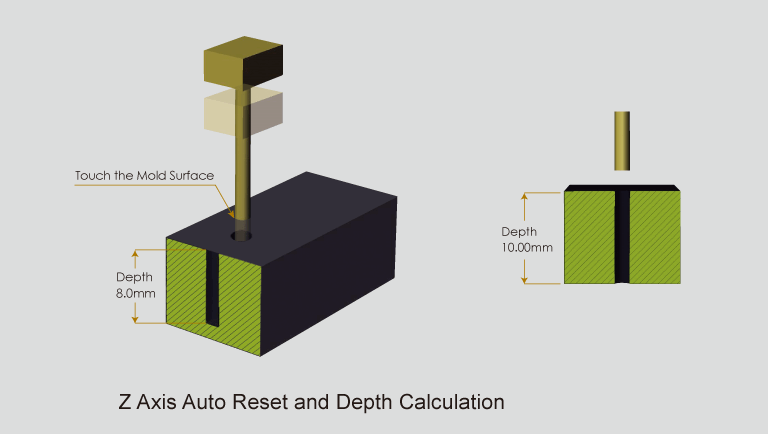

- Z axis auto reset and depth calculation. (Z axis automatically checks depths of holes, and then returns in order to complete any that are too shallow.)

Specifications

- Work table dimension (mm) 500× 500

- Max. Workpiece dimension (mm) 990 × 490

- Table travel X/Y (mm) 350 × 250

- Z axis travel(mm) 350

- Ram servo travel (mm) 150

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 1000 / 1200

- Packing dimension (mm) 1800 × 1500 × 2240

- Machine structure C-type

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 600× 700

- Max. Workpiece dimension (mm) 800 × 1120

- Table travel X/Y (mm) 500 × 600

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2300 / 2500

- Packing dimension (mm) 1900 × 1700 × 2400

- Machine structure Double Column

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

Accessories

- 01.Electrode pipe guide Ø1.0mm

- 02.Electrode tube Ø1.0mm × 10

- 03.Halogen work lamp

- 04.Tool box × 1

- 05.Filter × 2

- 06.Parallel block 1set

- 07.X, Y, Z axis precision ball screw

- 08.Auto pressure release pump × 1

- 09.X, Y, Z axis precision servo motor

- 10.1μ 2 axis optical scale and LCD

- 11.X, Y, Z axis hand wheel

- 12.USB

- 13.X, Y, Z axis linear guideway

- 14.Electrode auto change system

- 15.Collet

Feature

- Mirror image function.

- Coordinates can rotate at any angle.

- Automatic copper tube deviation correction.

- Automatic 16 & 30 copper tube changers available.

- Direct and easy learning dialogue operation interface.

- Data could be input by USB, or transfer through network.

- Automatic edge, internal diameter finding, and centering.

- The machining coordinate can be input directly when NC program is not available.

- Drilling capacity from 0.2 mm to 3.0 mm diameter brass or copper electrode tubes.

- Automatic illustrates the path of current and next drilling position with color.

- Precision servo motors on X,Y,Z axes provide excellent stability during drilling.

- The flushing medium used by this machine is distilled water - environment friendly.

- Provide 1μ optical scale, linear slideway and ballscrew ensure very accurate movements.

- Z axis auto reset and depth calculation. (Z axis automatically checks depths of holes, and returns to complete any that are too shallow.)

- Spindle shaper head, X & Y axes motion on head , fixed bed; for automotive applications and other small bore machining on sheet metal molds/dies.

- NC program G-code and DXF files could be directly read; Automatically finds the start cutting point and begins a fine hole drilling process.

Specifications

- Work table dimension (mm) 500× 500

- Max. Workpiece dimension (mm) 990 × 490

- Table travel X/Y (mm) 350 × 250

- Z axis travel(mm) 350

- Ram servo travel (mm) 150

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 1000 / 1200

- Packing dimension (mm) 1800 × 1500 × 2240

- Machine structure C-type

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 515 × 390

- Max. Workpiece dimension (mm) 975 x 740

- Table travel X/Y (mm) 400 × 300

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2000 / 2200

- Packing dimension (mm) 2300 × 1800 × 2240

- Machine structure Traveling Head

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 600× 700

- Max. Workpiece dimension (mm) 800 × 1120

- Table travel X/Y (mm) 500 × 600

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2300 / 2500

- Packing dimension (mm) 1900 × 1700 × 2400

- Machine structure Double Column

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 660 x 490

- Max. Workpiece dimension (mm) 1185 x 740

- Table travel X/Y (mm) 600 x 300

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2100 / 2300

- Packing dimension (mm) 2300 x 1800 x 2240

- Machine structure Traveling Head

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

Accessories

- 01.Electrode pipe guide Ø1.0mm

- 02.Electrode tube Ø1.0mm × 10

- 03.Halogen work lamp

- 04.Tool box × 1

- 05.Filter × 2

- 06.Parallel block 1set

- 07.X, Y, Z axis precision ball screw

- 08.Auto pressure release pump × 1

- 09.X, Y, Z axis precision servo motor

- 10.1μ 2 axis optical scale and LCD

- 11.X, Y, Z axis hand wheel

- 12.USB

- 13.X, Y, Z axis linear guideway ( For KTC 430 and above )

- 14.Electrode auto change system

- 15.Collet

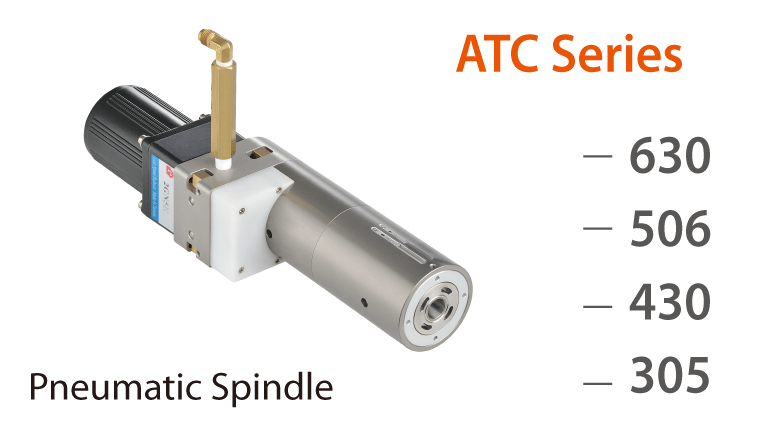

Feature

- Mirror image function.

- Coordinates can rotate at any angle.

- Automatic copper tube deviation correction.

- Automatic 16 & 30 copper tube changers available.

- Direct and easy learning dialogue operation interface.

- Data could be input by USB, or transfer through network.

- Automatic edge, internal diameter finding, and centering.

- Drilling capacity from 0.2 mm to 3.0 mm diameter brass or copper electrode tubes.

- Automatic illustrates the path of current and next drilling position with color.

- The machining coordinate can be input directly when NC program is not available.

- Precision servo motors on X,Y,Z axes provide excellent stability during drilling.

- The flushing medium used by this machine is distilled water - environment friendly.

- Provide 1μ optical scale, linear slideway and ballscrew ensure very accurate movements.

- Z axis auto reset and depth calculation. (Z axis automatically checks depths of holes, and returns to complete any that are too shallow.)

- NC program G-code and DXF files could be directly read; Automatically finds the start cutting point and begins a fine hole drilling process.

Specifications

- Work table dimension (mm) 500× 500

- Max. Workpiece dimension (mm) 990 × 490

- Table travel X/Y (mm) 350 × 250

- Z axis travel(mm) 350

- Ram servo travel (mm) 150

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 1000 / 1200

- Packing dimension (mm) 1800 × 1500 × 2240

- Machine structure C-type

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 515 × 390

- Max. Workpiece dimension (mm) 975 x 740

- Table travel X/Y (mm) 400 × 300

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2000 / 2200

- Packing dimension (mm) 2300 × 1800 × 2240

- Machine structure Traveling Head

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 600× 700

- Max. Workpiece dimension (mm) 800 × 1120

- Table travel X/Y (mm) 500 × 600

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2300 / 2500

- Packing dimension (mm) 1900 × 1700 × 2400

- Machine structure Double Column

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 660 x 490

- Max. Workpiece dimension (mm) 1185 x 740

- Table travel X/Y (mm) 600 x 300

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2100 / 2300

- Packing dimension (mm) 2300 x 1800 x 2240

- Machine structure Traveling Head

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

Accessories

- 01.Electrode pipe guide Ø1.0mm

- 02.Electrode tube Ø1.0mm × 10

- 03.Halogen work lamp

- 04.Tool box × 1

- 05.Filter × 2

- 06.Parallel block 1set

- 07.X, Y, Z axis precision ball screw

- 08.Auto pressure release pump × 1

- 09.X, Y, Z axis precision servo motor

- 10.1μ 2 axis optical scale and LCD

- 11.X, Y, Z axis hand wheel

- 12.USB

- 13.X, Y, Z axis linear guideway ( For KTC 430 and above )

- 14.Electrode auto change system

- 15.Collet

Feature

- Mirror image function.

- Coordinates can rotate at any angle.

- Automatic copper tube deviation correction.

- Direct and easy learning dialogue operation interface.

- Automatic 16 & 30 copper tube changers available.

- Data could be input by USB, or transfer through network.

- Automatic edge, internal diameter finding, and centering.

- The machining coordinate can be input directly when NC program is not available.

- Drilling capacity from 0.2 mm to 3.0 mm diameter brass or copper electrode tubes.

- Automatic illustrates the path of current and next drilling position with color.

- Precision servo motors on X,Y,Z axes provide excellent stability during drilling.

- The flushing medium used by this machine is distilled water - environment friendly.

- Provide 1μ optical scale, linear slideway and ballscrew ensure very accurate movements.

- Z axis auto reset and depth calculation. (Z axis automatically checks depths of holes, and returns to complete any that are too shallow.)

- Spindle shaper head, X & Y axes motion on head ,fixed bed; for automotive applications and other small bore machining on sheet metal molds/dies.

- NC program G-code and DXF files could be directly read; Automatically finds the start cutting point and begins a fine hole drilling process.

Specifications

- Work table dimension (mm) 500× 500

- Max. Workpiece dimension (mm) 990 × 490

- Table travel X/Y (mm) 350 × 250

- Z axis travel(mm) 350

- Ram servo travel (mm) 150

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 1000 / 1200

- Packing dimension (mm) 1800 × 1500 × 2240

- Machine structure C-type

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 515 × 390

- Max. Workpiece dimension (mm) 975 x 740

- Table travel X/Y (mm) 400 × 300

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2000 / 2200

- Packing dimension (mm) 2300 × 1800 × 2240

- Machine structure Traveling Head

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 600× 700

- Max. Workpiece dimension (mm) 800 × 1120

- Table travel X/Y (mm) 500 × 600

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2300 / 2500

- Packing dimension (mm) 1900 × 1700 × 2400

- Machine structure Double Column

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

- Work table dimension (mm) 660 x 490

- Max. Workpiece dimension (mm) 1185 x 740

- Table travel X/Y (mm) 600 x 300

- Z axis travel(mm) 350

- Ram servo travel (mm) 350

- Max. Length of electrode (mm) 400

- Min. Electrode diameter (mm) Ø0.2 ~ Ø3.0

- Max. Workpiece weight (kgs) 500

- Dielectric Water

- Capacity of dielectric (litres) 100

- Machine weight (nw/gw) (kg) 2100 / 2300

- Packing dimension (mm) 2300 x 1800 x 2240

- Machine structure Traveling Head

- Max. Current (A) 25

- Peak current setting (ip) (steps) 6

- Pulse on-time setting (steps) 9

- Pulse off-time setting (steps) 9

- High volts (steps) 3

- Power input (V) 220/ 380/ 415

- Max. Rating power (KVA) 4

Accessories

- 01.Electrode pipe guide Ø1.0mm

- 02.Electrode tube Ø1.0mm × 10

- 03.Halogen work lamp

- 04.Tool box × 1

- 05.Filter × 2

- 06.Parallel block 1set

- 07.X, Y, Z axis precision ball screw

- 08.Auto pressure release pump × 1

- 09.X, Y, Z axis precision servo motor

- 10.1μ 2 axis optical scale and LCD

- 11.X, Y, Z axis hand wheel

- 12.USB

- 13.X, Y, Z axis linear guideway ( For KTC 430 and above )

- 14.Electrode auto change system

- 15.Collet